Products

- Aluminium Die Casting

- Suspension

- Transmission

- Braking Systems

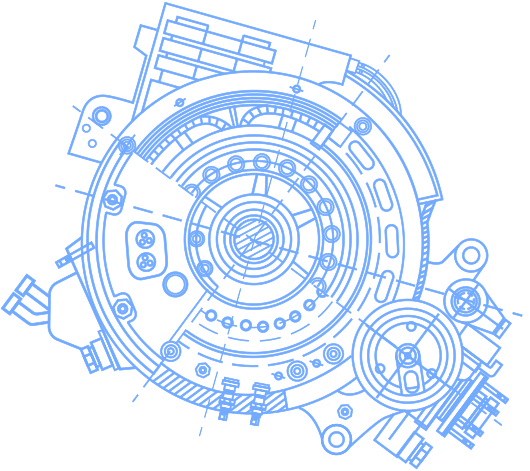

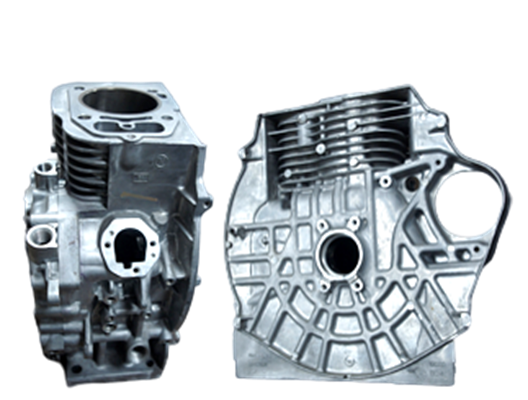

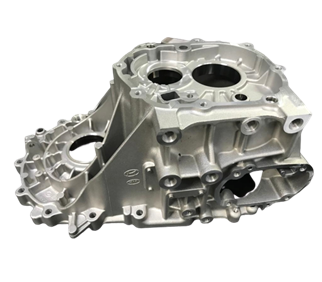

Aluminium Die Casting

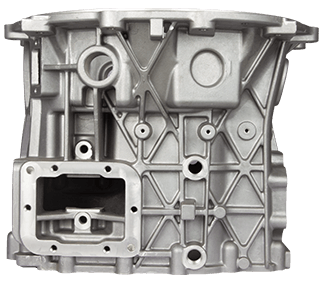

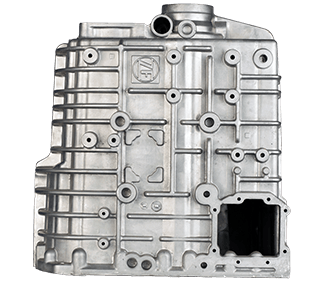

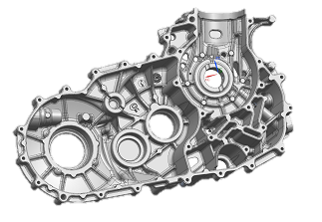

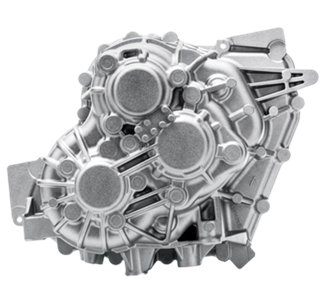

Commercial Vehicle Gear Box Housing

Commercial Vehicle Transmission Housing

Commercial Vehicle Gear Box Housing

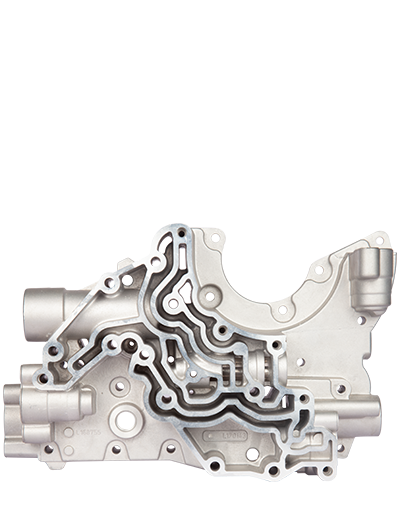

Passenger Vehicle Case Transmission

Passenger Vehicle Oil Cooler Housing

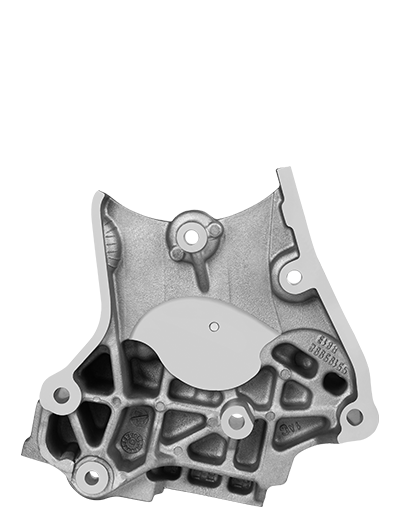

Passenger Vehicle Clutch Housing

Passenger Vehicle Engine Mounting Bracket

Passenger Vehicle Rack Pinion Housing

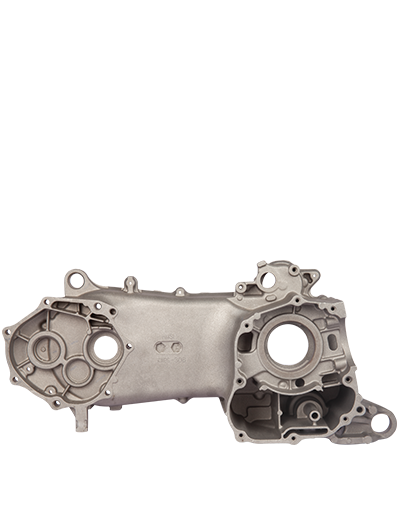

Two Wheeler Crankcase (Transmission)

Two Wheeler Crankcase (LH)

Two Wheeler Crankcase (RH)

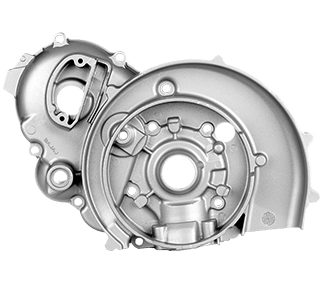

Two Wheeler Magneto Cover

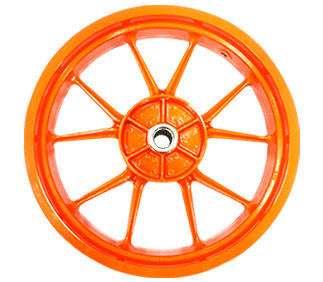

Two Wheeler Alloy Wheel - Disc Brake

Two Wheeler Alloy Wheel Rear - Disc + ABS Brake

Two Wheeler EV Alloy Wheel

Two Wheeler Alloy Wheel

Two Wheeler Alloy Wheel - Drum Brake

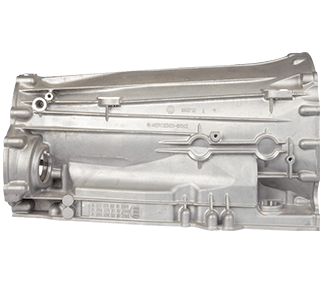

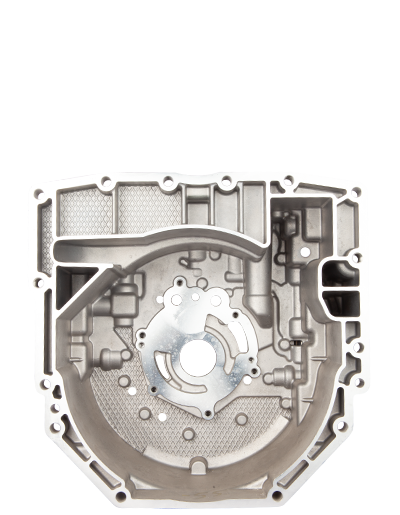

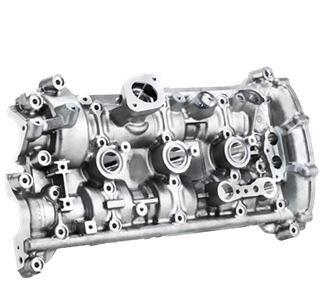

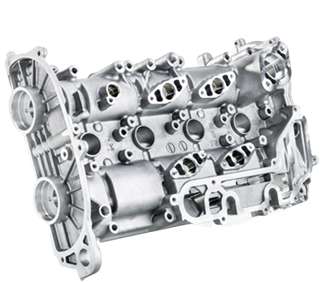

Passenger Vehicle Transmission Case

Passenger Vehicle Cam Cover

Passenger Vehicle Cam Carrier with Bearing Frame

Two Wheeler Swing Arm

Two Wheeler Swing Arm

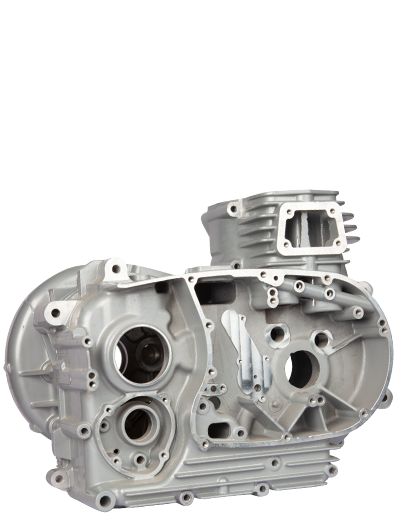

Three Wheeler Crankcase with Cylinder Block

Two Wheeler Handle Grip

Passenger Vehicle Transmission Case

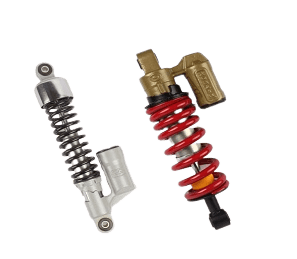

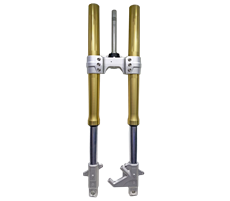

Suspension

Two Wheeler Inverted Front Fork Assembly (Cartridge Type)

Two Wheeler Front Fork Assembly (with Protection Cover)

Two Wheeler Front Fork Leg

Two Wheeler Mono Shock Absorber (Twin tube)

Two Wheeler Gas Filled Shock Absorber (Canister Type)

Two Wheeler Mono Shock Absorber (Mono Tube)

Two Wheeler Spring in Spring Shock Absorber

Two Wheeler Front Fork Assembly

Two Wheeler Front Fork Assembly

Three Wheeler Suspension

Four Wheeler Suspension

Inverted Front Fork Assembly (Adjustable Type)

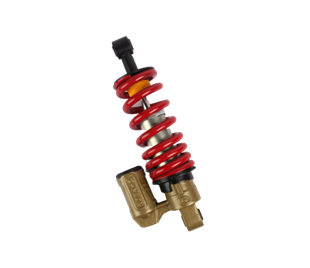

Two Wheeler Rear Mono Shock Absorber (Adjustable Damping)

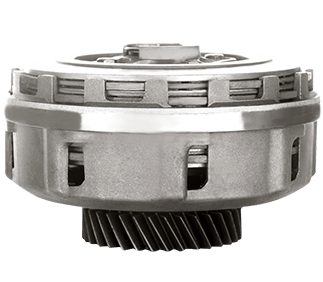

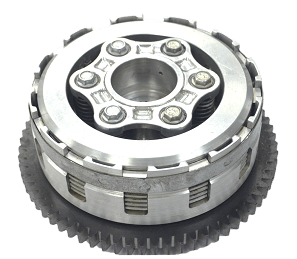

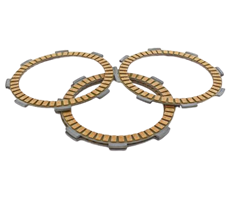

Transmission

Three Wheeler Clutch Assembly

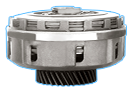

Two Wheeler Clutch Assembly (400 cc)

Two Wheeler Assist and Slip (ANS) Clutch Assembly (300 - 1800 cc)

Two Wheeler Automatic Clutch Assembly (400 - 1800 cc)

Two Wheeler Cork Friction Plates

Two Wheeler Paper Friction Plates

Two Wheeler Continuous Variable Transmission (CVT 100 - 125 cc)

Two Wheeler Continuous Variable Transmission (CVT 125 - 150 cc)

Two Wheeler Continuous Variable Transmission (CVT 150 - 180 cc)

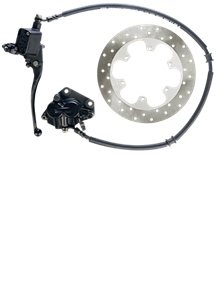

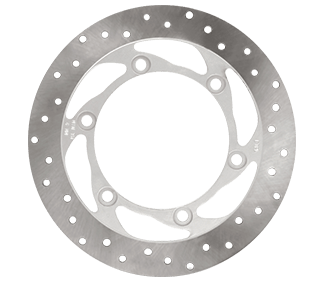

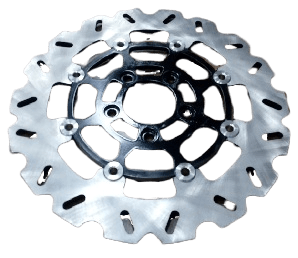

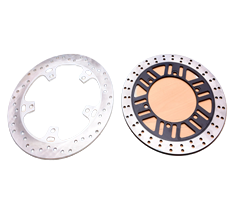

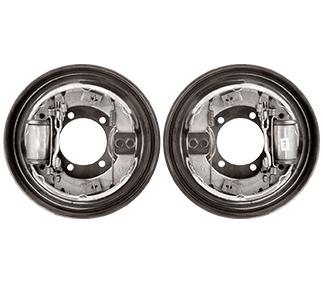

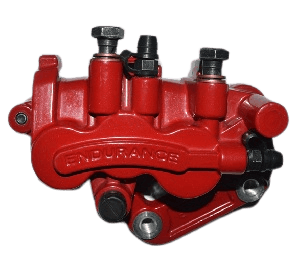

Braking Systems

Two Wheeler Brake Disc

Two Wheeler Floating Brake Disc

Two Wheeler Brake Disc

Two Wheeler Disc Brake Assembly

Three Wheeler Front Drum Brake Assembly

Three Wheeler Rear Brake Panel Assembly

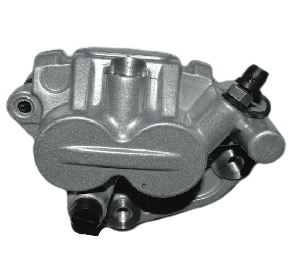

Two Wheeler Radial Caliper Assembly

Two Wheeler Rear Brake Caliper Assembly

Two Wheeler 3 POT Front Brake Caliper Assembly

Two Wheeler 2 Pot Front Brake Caliper Assembly

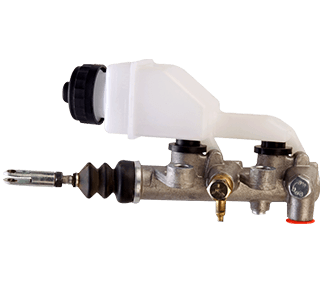

Two Wheeler CBS Master Cylinder Assembly

Two Wheeler Rear Brake Caliper Assembly

Three Wheeler Tandem Master Cylinder

Two Wheeler Anti-lock Braking System Modulator

Latest @ Endurance

Endurance recognized as Best Managed Company – 2022

2022 | Best Managed Company

Recognition as Best Managed Company – 2022

Endurance Technologies has been recognized as among India’s “Best M…

Supplier Quality Excellence Award by General Motors

2020 | Overseas Award

GM | 2019 Supplier Quality Excellence Award

Endurance Overseas , News

We’re glad to announce that ENDURANCE SPA won GM Supplier Quality Excellence Award for the outstanding 2019 perfo…

This ancillary company is beating the demand blues of two-wheeler makers

2020 | ET Bureau

GM | 2019 Supplier Quality Excellence Award

Endurance Overseas , News

We’re glad to announce that ENDURANCE SPA won GM Supplier Quality Excellence Award for the outstanding 2019 perfo…

Endurance has acquired Grimeca Srl, Italy for 2W Braking System Technology

2020 | Italy

Chh. Sambhajinagar (India)-based tier 1, Endurance Technologies has made another acquisition in a span of two months. Endurance Tech has acquired 100 percent stake in Italy-based Grimeca Srl (for 2W Brakin…

Acquisition of Adler SpA by Endurance Technologies

2020 | Italy

Endurance Adler

16.04.2020 , Endurance Overseas , news 100

Acquisition of Adler SpA by Endurance Overseas Srl

Turin, April 15th 2020

We inform you that Endurance Overseas S.r….

Endurance Technologies Ltd has Won 1st Prize in National Energy Conservation Award-2019

2019 | New Delhi

Endurance Technologies Ltd – has Won 1st Prize in “National Energy Conservation Award-2019 ” under Manufacturing sector at the hands of Hon. Minister of Power &…

Endurance Technologies buys Italian company for $9.3 mn

2019 | Mumbai

Recognition as Best Managed Company – 2022

Endurance Technologies has been recognized as among India’s “Best M…

A reviving two wheeler market is shaping the future of this company

2018 | Mumbai

Fifty-six-year-old businessman Anurang Jain is focused on growing his company’s profit at a faster pace to revenue. In the last five consecutive years, auto component maker Endurance Technologies h…

An enduring ride: Endurance Technologies exhilarating journey to Rs 5,000 crore

2018 | Mumbai

Anurang Jain, with a net worth of $1.5 billion, has debuted on Forbes’s The World’s Billionaires list at rank 1561

Image: Mexy Xavier

In the ten years to 2005, Anurang Jain a…

Endurance received The Grand Award for QCDDM Performance for 2016-17 from Honda Scooters and Motorcycles India (HMSI)

2017 |

Endurance Technologies Ltd received The Grand Award for QCDDM Performance for 2016-17 from Honda Scooters & Motorcycles India (HMSI) on outstanding performance.

Endurance Technologies to set up test track, expand product portfolio

2017 |

Endurance Technologies to set up test track, expand product portfolio

Endurance Technologies IPO subscribed 43.7 times on final day

2016 | Mumbai

Endurance Technologies IPO subscribed 43.7 times on final day

Endurance recognized as Best Managed Company – 2022

2022 | Best Managed Company

Recognition as Best Managed Company – 2022

Endurance Technologies has been recognized as among India’s “Best M…

Supplier Quality Excellence Award by General Motors

2020 | Overseas Award

GM | 2019 Supplier Quality Excellence Award

Endurance Overseas , News

We’re glad to announce that ENDURANCE SPA won GM Supplier Quality Excellence Award for the outstanding 2019 perfo…

This ancillary company is beating the demand blues of two-wheeler makers

2020 | ET Bureau

GM | 2019 Supplier Quality Excellence Award

Endurance Overseas , News

We’re glad to announce that ENDURANCE SPA won GM Supplier Quality Excellence Award for the outstanding 2019 perfo…

Endurance has acquired Grimeca Srl, Italy for 2W Braking System Technology

2020 | Italy

Chh. Sambhajinagar (India)-based tier 1, Endurance Technologies has made another acquisition in a span of two months. Endurance Tech has acquired 100 percent stake in Italy-based Grimeca Srl (for 2W Brakin…

Acquisition of Adler SpA by Endurance Technologies

2020 | Italy

Endurance Adler

16.04.2020 , Endurance Overseas , news 100

Acquisition of Adler SpA by Endurance Overseas Srl

Turin, April 15th 2020

We inform you that Endurance Overseas S.r….

Endurance Technologies Ltd has Won 1st Prize in National Energy Conservation Award-2019

2019 | New Delhi

Endurance Technologies Ltd – has Won 1st Prize in “National Energy Conservation Award-2019 ” under Manufacturing sector at the hands of Hon. Minister of Power &…

Endurance Technologies buys Italian company for $9.3 mn

2019 | Mumbai

Recognition as Best Managed Company – 2022

Endurance Technologies has been recognized as among India’s “Best M…

A reviving two wheeler market is shaping the future of this company

2018 | Mumbai

Fifty-six-year-old businessman Anurang Jain is focused on growing his company’s profit at a faster pace to revenue. In the last five consecutive years, auto component maker Endurance Technologies h…

An enduring ride: Endurance Technologies exhilarating journey to Rs 5,000 crore

2018 | Mumbai

Anurang Jain, with a net worth of $1.5 billion, has debuted on Forbes’s The World’s Billionaires list at rank 1561

Image: Mexy Xavier

In the ten years to 2005, Anurang Jain a…

Endurance received The Grand Award for QCDDM Performance for 2016-17 from Honda Scooters and Motorcycles India (HMSI)

2017 |

Endurance Technologies Ltd received The Grand Award for QCDDM Performance for 2016-17 from Honda Scooters & Motorcycles India (HMSI) on outstanding performance.

Endurance Technologies to set up test track, expand product portfolio

2017 |

Endurance Technologies to set up test track, expand product portfolio

Endurance Technologies IPO subscribed 43.7 times on final day

2016 | Mumbai

Endurance Technologies IPO subscribed 43.7 times on final day

About Us

FY 2023-24

We are committed to

Quality

Process

Technology

Education

Every child deserves to reach her or his full potential. However, gender inequalities in their communities hinder this reality. We envision a society where all…

Health Sanitation

Health is a basic human right for every individual. We are driving health and hygiene initiatives in villages around Chh. Sambhajinagar. These initiatives include… installing RO plants to ensure access to clean drinking water. We are also renovating government hospitals to increase access for communities, building toilets, organizing health check-ups and surgeries, providing rehab to alcoholics, and conducting yoga sessions. We are focused on improving women’s health which has a positive ripple effect, transforming families and communities.

Livelihood

We are committed to empowering individuals, especially women fulfill their dreams. We work with women in villages to understand their interests, develop their skills…

Environment

In order to ensure development and sustainability of communities, protecting our environment is crucial. We believe in investing in renewable sources of energy…

Education

Every child deserves to reach her or his full potential. However, gender inequalities in their communities hinder this reality. We envision a society where all…

Health Sanitation

Health is a basic human right for every individual. We are driving health and hygiene initiatives in villages around Chh. Sambhajinagar. These initiatives include… installing RO plants to ensure access to clean drinking water. We are also renovating government hospitals to increase access for communities, building toilets, organizing health check-ups and surgeries, providing rehab to alcoholics, and conducting yoga sessions. We are focused on improving women’s health which has a positive ripple effect, transforming families and communities.

Livelihood

We are committed to empowering individuals, especially women fulfill their dreams. We work with women in villages to understand their interests, develop their skills…

Environment

In order to ensure development and sustainability of communities, protecting our environment is crucial. We believe in investing in renewable sources of energy…

Proactively take new opportunities to become the best version of yourself.

Innovation