Innovation at a Glance

"ASPIRE" an initiative to nurture innovation culture

Featured Innovation

ENDURANCE PROVING GROUND

We are the first tier 1 supplier in India to develop a state-of-the-art proving ground to test our products directly on the vehicle. Spread across 29 acres, the Endurance Proving Ground (EPG), enables us to test our suspension, transmission and braking products across different surfaces including high speed performance track, ride evaluation track, ABS evaluation track, ride & handling track, gradient track, steering pad, mud & water trough, dust tunnel & country track. EPG is managed from a central control tower at the Operations Centre which includes the fully-equipped confidential workshops required for preparing the vehicles for testing, riders’ rest areas and the test track maintenance building. EPG has certified test riders trained by global experts in vehicle riding and evaluation of suspension, transmission & braking products.

ARAI (Automotive Research Association of India) has certified our EPG for testing two and three wheeled vehicles.

- 1985-1995

- 1996-2000

- 2001-2005

- 2006-2010

- 2011-2015

- 2016-2020

- 2021-2023

Our Innovation Categories

Our Innovation Categories

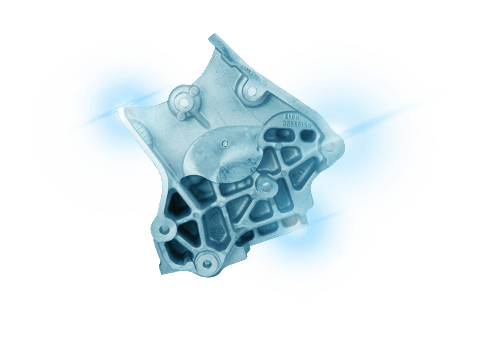

Aluminium Die Casting

Aluminium Die Casting

Endurance is the largest Aluminium die-casting organization in India. We are the market leaders in Aluminium die-casting and machining for 2, 3 & 4 wheelers. With over three decades of experience in design, development, and manufacturing of high pressure, low pressure, and gravity die-casting products for Indian and overseas OEMs, we have developed our capabilities and continuously strive for excellence. We are the first Indian organization to receive NADCA (North American Die Casters Association) Award for excellence in Aluminium die-casting in Ohio. Our overseas business in Italy and Germany caters to leading global 4 wheeler OEMs. We have acquired business for hybrid and electric vehicle models too. We have developed expertise in process conversion such as converting gravity die-casting, cast iron, and fabricated parts assembly to high pressure die-casting. We continue to innovate and use the latest technologies to ensure first time right products, increase the die life and enhance quality. Die-casting manufacturing also have support from our own state of the art tool room facility for design to develop dies in a highly technology enabled environment.

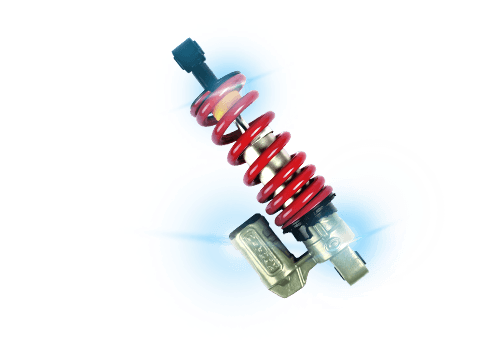

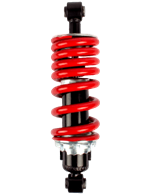

Suspension

Suspension

We design and manufacture a wide range of front forks and shock absorbers to provide safe, stable and comfortable driving experience across all the road surfaces. We are equipped with best in class equipment to test and validate our suspension products simulating the wide range of road conditions making the products more reliable and safe. We are committed to make our products safer, lighter, more durable, reliable, and environment friendly to reduce carbon footprint. We are the only company in India to design, develop and manufacture inverted front forks and mono shock absorbers, serving our Indian & overseas customers. We continue to innovate and develop higher end suspension products including mechanical and electronic adjustable damping force forks & shock absorbers with hydraulic spring force adjustment, air suspension system and semi-active suspension systems to deliver best in class riding experience.

Transmission

Transmission

Endurance is a well-established player in transmission systems for 2 & 3 wheelers. With over two decades of experience on Indian driving habits, we design, develop and manufacture a wide range of reliable clutches and CVTs. We have built capabilities to ensure first time right and design innovative products through VAVE. We test our products by simulating the exact vehicle operating conditions as well as test our products on the vehicle to deliver reliability and performance. We have developed cork & paper type friction clutches, highly fuel efficient CVT designs and VAVE designs of Anti-hop clutches. The Endurance anti-hop clutches offer enhanced performance during downshifting, sudden braking and takeoff leading to better vehicle stability.

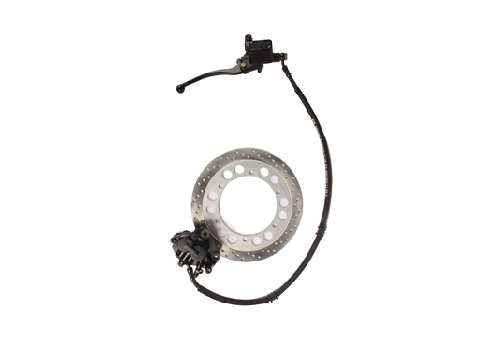

Braking Systems

Braking Systems

Endurance is a leading player in high performance braking solutions for 2 & 3 wheelers. With over 14 years of experience, we have developed capabilities to deliver reliable and first time right products to our customers. Our braking solutions are designed for lesser stopping distance and better stability during deceleration, thereby ensuring rider safety. Being safety products, every component of our brake system is designed for increased structural rigidity and durability. Our products undergo rigorous testing for performance and durability using the best in class testing equipment in our in-house R&D facility. We also take utmost care in selecting the finest and environment friendly friction linings and tune our braking systems. We design, manufacture and deliver fully hydraulic as well as hydro mechanical type CBS with both Disc/Disc and Disc/drum combinations. We offer hydraulic drum brake systems with our patented integral strut assembly with external parking lever mechanism. In addition to these innovations, we have partnered with a leading ABS manufacturer to design, develop, and manufacture ABS systems for 2-wheelers which will be in mass production in 2021.

Presence across the world

We have 5 dedicated DSIR (Department of Scientific and Industrial Research) approved R&D Centres located in Chh. Sambhajinagar and Pune, India for each of our product verticals. There are 2 Technical Centres located in Turin and Rovereto, Italy.